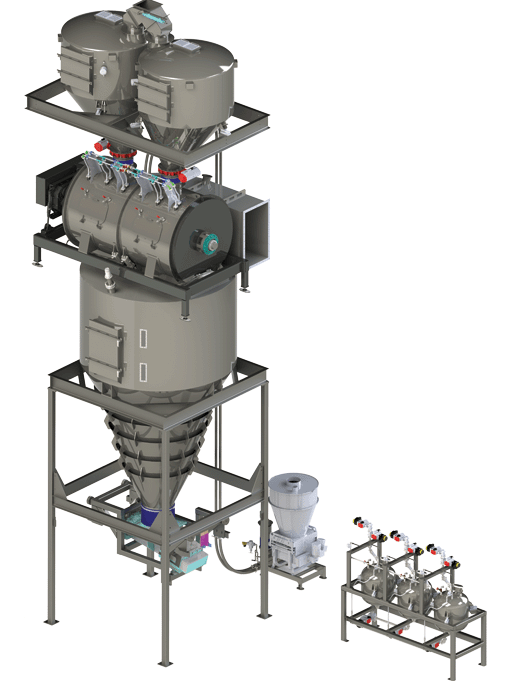

Since 1985, the Extru-Tech name has been synonymous with versatility and efficiency among food and feed manufacturers. Designed to be integral and stackable with the Extru-Tech Vertical Cooler to optimize installation, the ETI Batch Coating System offers benefits and capabilities never before available with traditional spinning disk or open drum coating systems. Plus, the Extru-Tech system offers the sanitary design and dosing accuracy demanded by today’s food safety and traceability requirements

The ETI Batch Coating System was designed to handle up to 40,000 lbs/hour at batch sizes of 2,500 pounds at 63% fill level. Even at this high rate, the batch coater provides 3.75 minutes of product retention time, which far exceeds the retention time of a traditional, continuous coating system. Batch retention times of up to 5 minutes are seen when operating near 24,000 lbs/hour production rates.