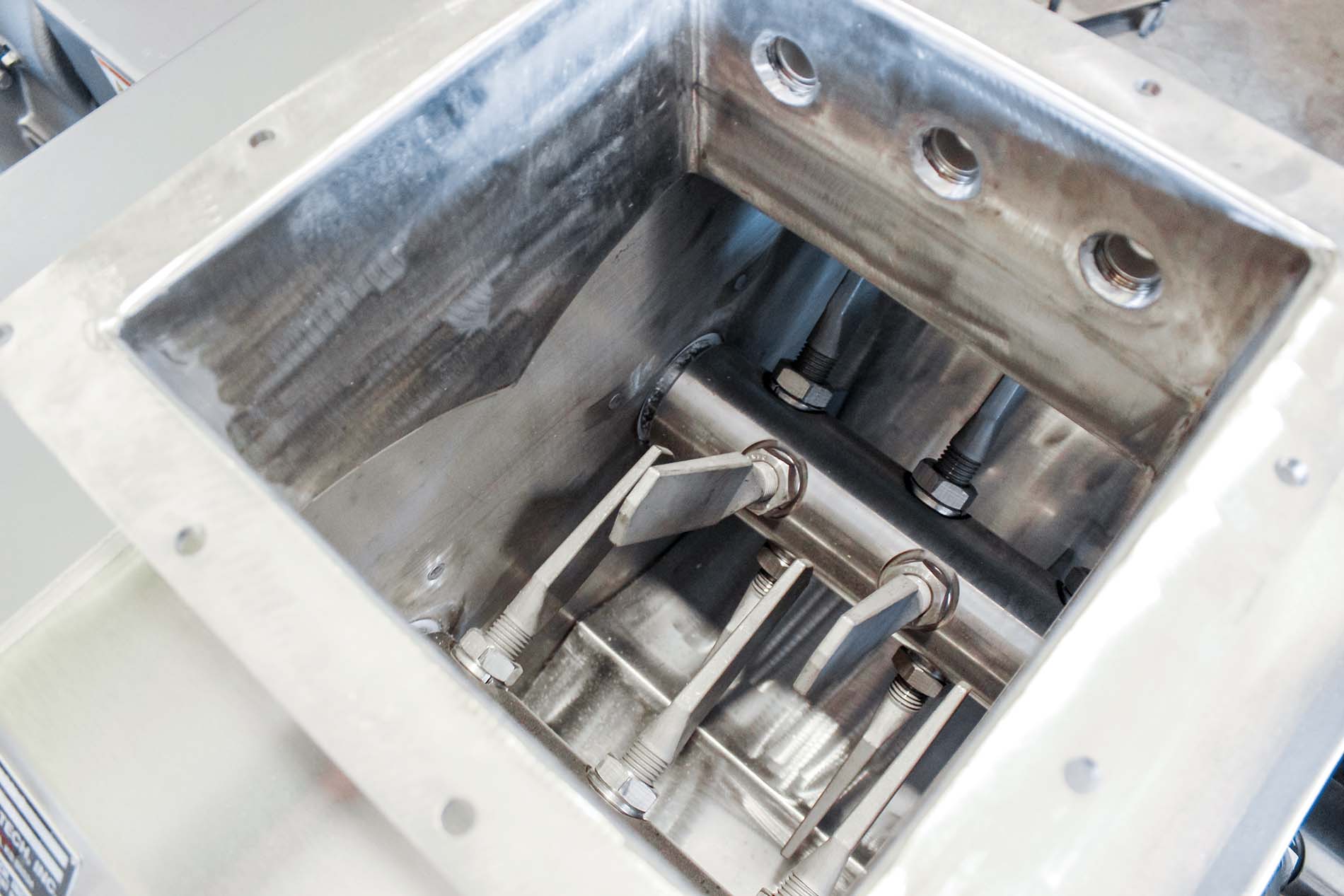

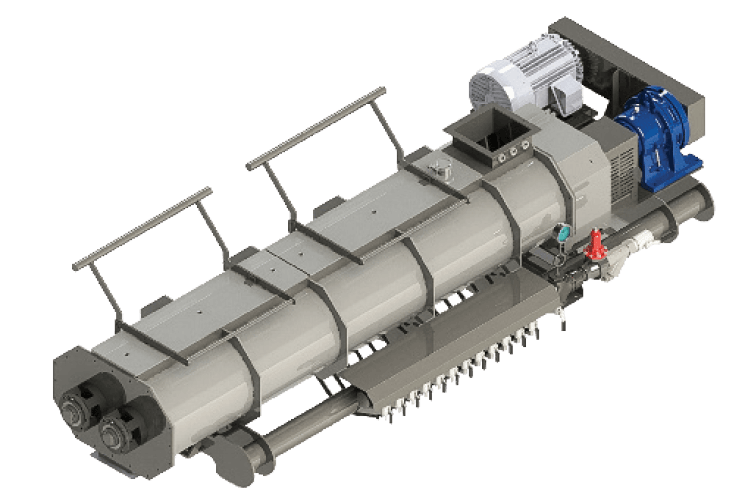

Advanced Feature paddle configurations allow for processing variability for tomorrow’s innovative products. These innovations include: proven first in first out product flow, variable mixing intensity, unsurpassed paddle strikes per minute and distributive mixing capabilities for High Meat/Oil products.