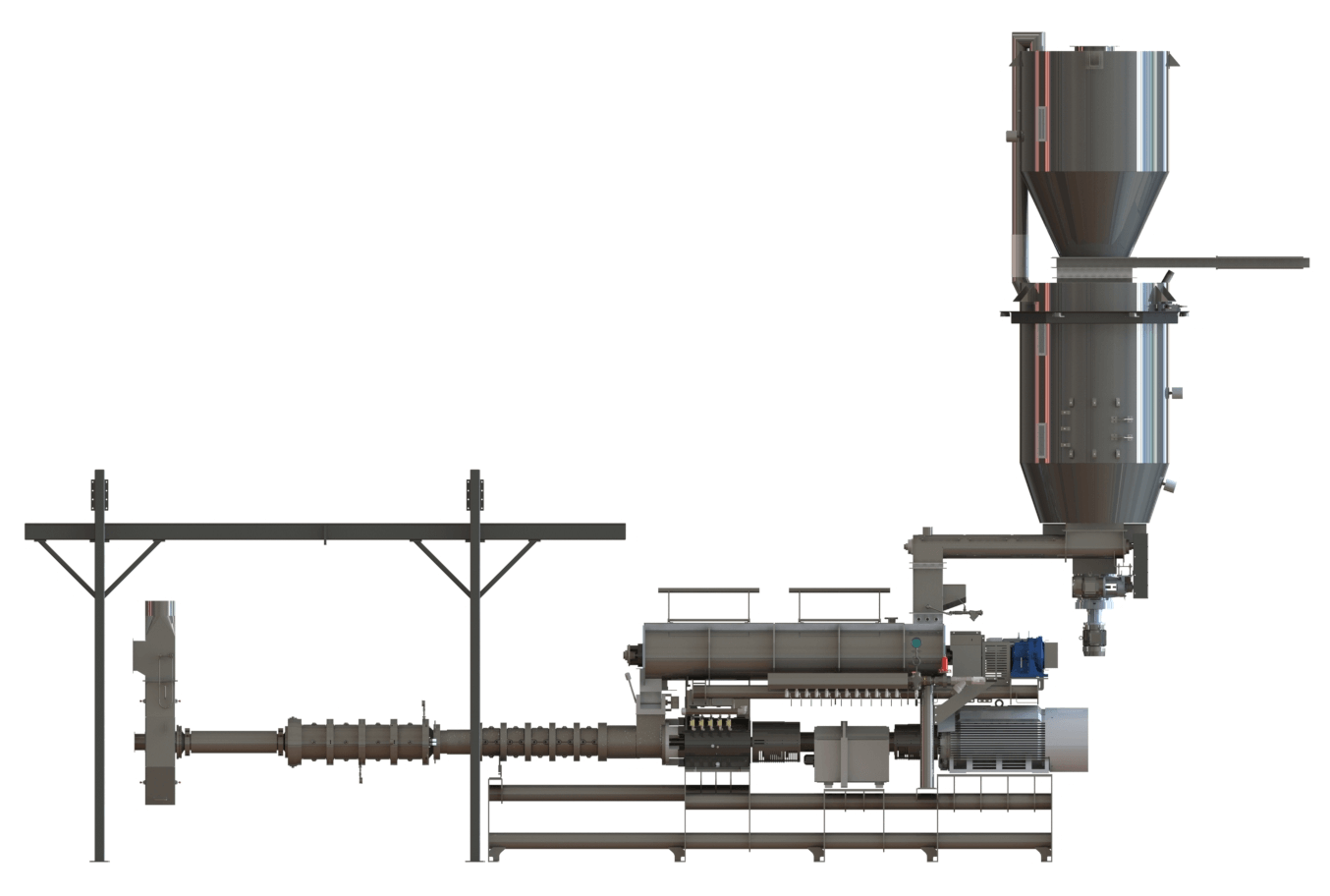

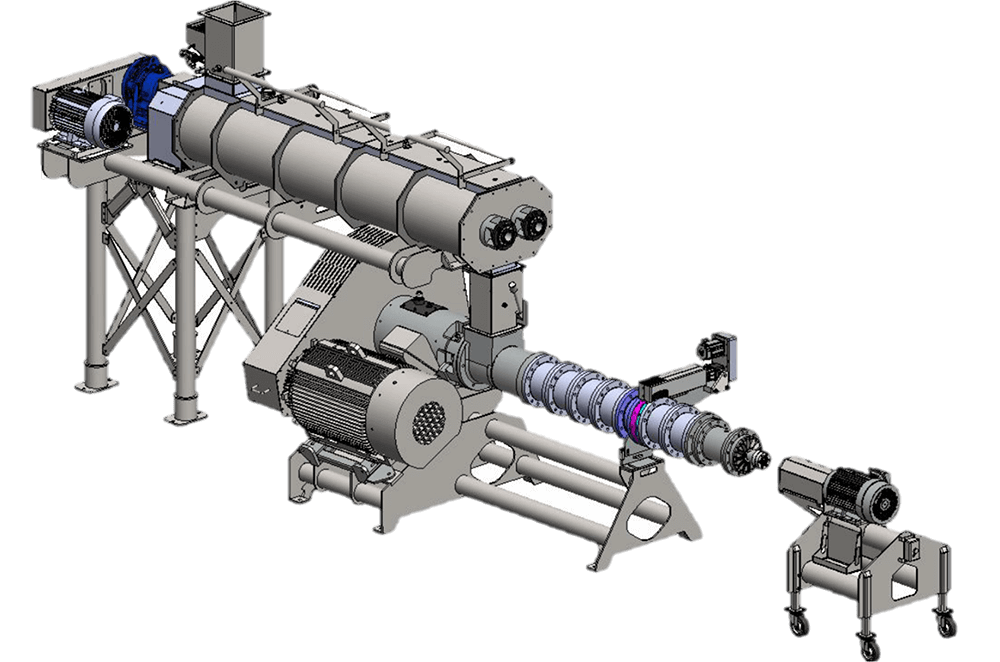

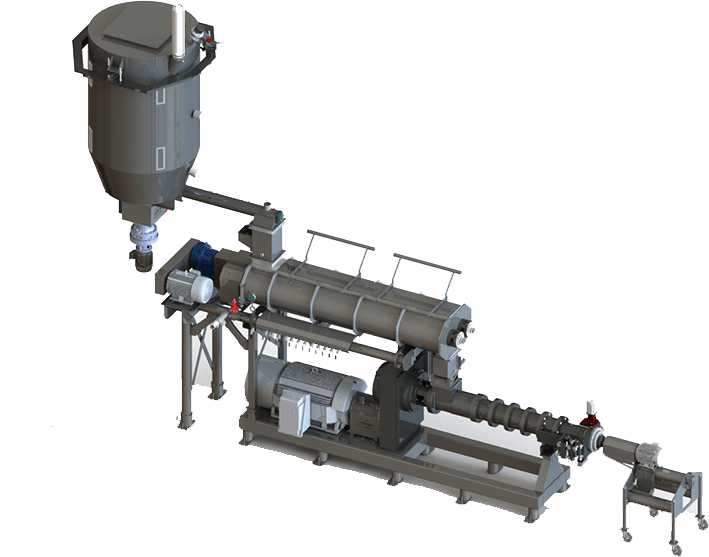

From unprecedented production capacities to exacting finished product quality, Extru-Tech Extrusion Cooking Systems have established the industry standards for performance and value. Extru-Tech’s Advanced Feature Extrusion systems were designed with two important criteria. The unit needed to be quick and easy to clean, and it needed to allow customers to control, reduce or eliminate contaminants in the system.

Each extruder model can be equipped with multiple barrel length packages, each designed for the production of specific product types. Naturally, all extruder screws and liners continue to be constructed of high quality, wear-resistant stainless steel alloys that are subsequently polished, heat-treated to required hardness specifications and then parallel ground to ensure proper fit between barrel components.